ISLAMABAD: Utilisation of 3D technology in Pakistan’s industrial sector can greatly enhance production capacity and efficiency, reduce waste, create job opportunities and drive economic growth, said Mubashir Rehman, Chief Executive Officer of Lahore-based Satpara Fabrics & Digital Textile Pakistan.

Talking to WealthPK, he said use of traditional methods in the textile industry was resulting in a lot of material wastage during different phases of production. “If Pakistan’s textile manufacturers start using 3D technology, they can reduce this waste by using inputs more sustainably,” he said.

It is proper to mention here that Pakistan’s textile exports plunged 20% in May 2023, meaning their value dropped to $1.31 billion during the month compared to $1.64 billion in the same month last year, according to the data released by Pakistan Bureau of Statistics.

Mubashir Rehman said: “Production processes are mainly dependent on fossil fuels, which produce harmful gases like carbon dioxide, nitrogen dioxide and sulphur dioxide that have harmful effects on both human life and environment.”

A report published by IQAir also ranked Pakistan third among the countries with the most polluted air.

“By adopting 3D technology, textile industry can also achieve the objective of protecting the environment from these harmful effects,” he maintained.

“Textile industry also extracts harmful chemicals like pesticides, toxic metals like lead, mercury, arsenic while manufacturing goods, which are then absorbed in water. So, adopting 3D technology in the industry will help overcome water pollution,” Mubashir Rehman said.

As per the Pakistan Council of Research in Water Resources, drinking water in 17 major cities is not suitable for human consumption, and in Lahore alone, 70% of water is contaminated.

“Traditional methods of designing textile products required a lot of manual work that took a long time and didn’t produce the desired results. But now, with 3D technology, textile manufacturers can use special computer programmes to make virtual 3D patterns and structures on fabrics. This makes it easier to see what the designs will look like and try them out quickly. It also saves time and money compared to the old ways of designing. By using 3D technology, designers can be more creative and come up with new ideas for fabric designs,” he explained.

“While traditional methods of manufacturing require big stocks of cloth, they entail spending a lot of money on its storage and transportation. By using 3D technology, the way the whole process works can be made simpler and more efficient. Textile makers can create things as needed. They don’t need to stock material and pay for rent of warehouses and transportation,” he added.

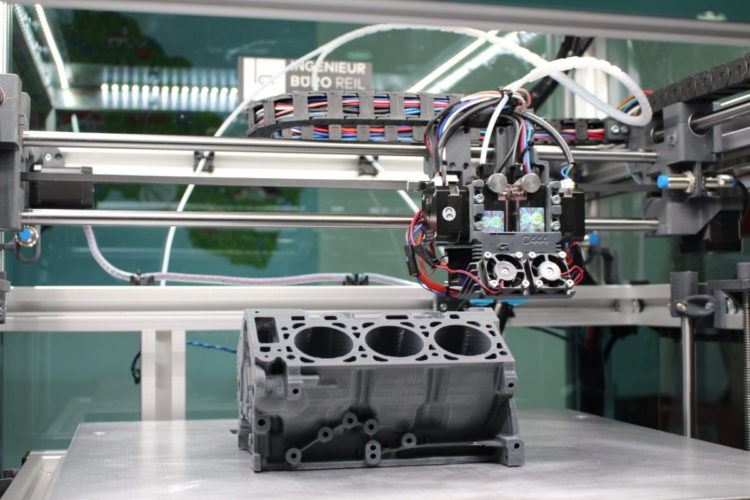

Mubashir Rehman said: “The use of 3D technology in Pakistan’s industrial sector will create opportunities for innovation and entrepreneurship. Small and medium-sized enterprises will have the ability to bring their ideas to life without requiring large initial investments. With the help of 3D printers, entrepreneurs can test their concepts, and improve their designs.”

As job opportunities in Pakistan become scarce, adopting 3D technology in the industry can create chances for people to learn new job-oriented skills like 3D printing and digital designing experts.

The government also needs to start training programmes to help people get these skills. –INP